Technology

The art of precision

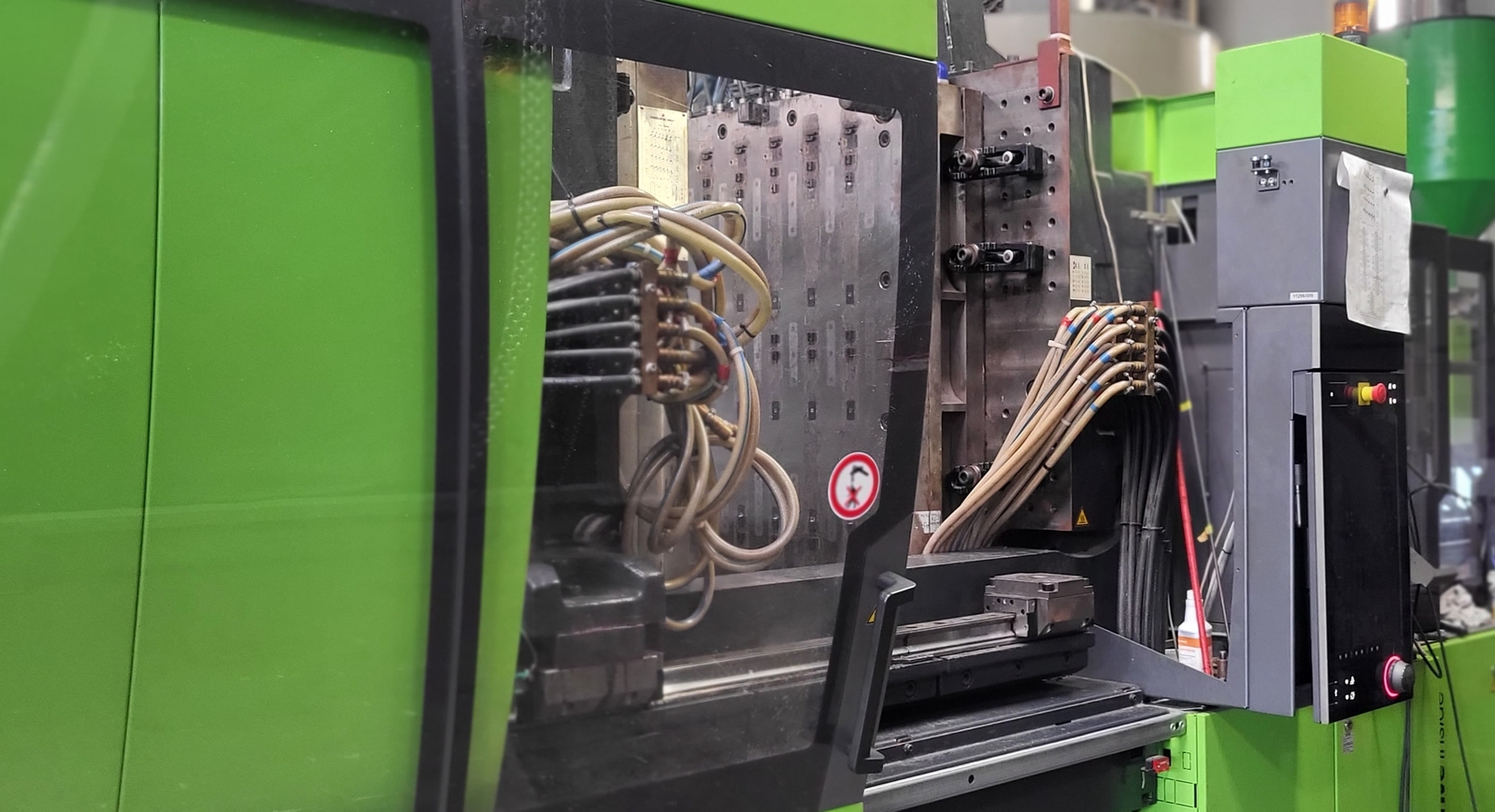

The plastic injection process is both an art and a science. It involves melting plastic granules and then injecting them under pressure into a mold, or matrix, which gives it the desired shape. This is where injection molding machines such as ENGEL and ARBURG ALLROUNDER come into play, offering unprecedented precision, speed and efficiency.

By controlling parameters such as temperature, pressure, speed and injection time, it is possible to produce products with complex shapes and precisely defined parameters.

Innovations

Modern injection technology is not only machines, but also advanced software enabling the design of products and dies with high accuracy. This enables efficient adaptation of plastic products to market needs. The technology we use enables us to form the basis for mass production of products tailored to the individual needs of our customers.

Sustainable development

One of the key aspects of injection technology is its impact on sustainable development. Energy-saving systems used in modern injection molding machines reduce energy consumption, while advanced recycling techniques allow production waste to be reused. This all leads to a smaller carbon footprint and more environmentally friendly production.

Technology supporting creativity

The possibilities offered by plastic injection are virtually limitless. From components used in construction to household items - this technology supports creativity and innovation in almost every area of life.